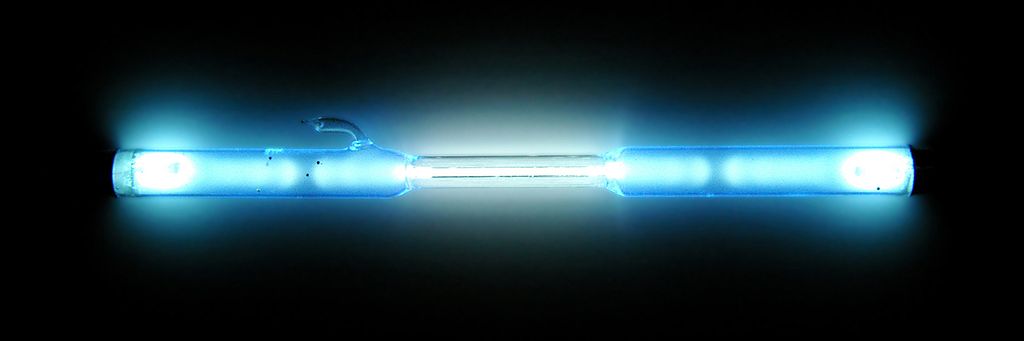

Mercury is an organic element found naturally in the Earth’s crust and an inorganic compound commonly used in manufacturing. Although thermometers and barometers come to mind when considering items manufactured using mercury, the compound can also be found in batteries and components using toggle controls.

While mercury was previously considered to be relatively harmless, scientific and medical research in the past 50 years or so has concluded that mercury can be toxic. As a result, many manufacturers have made the switch from mercury to non-mercury component manufacturing. But, of course, each approach has pros and cons, and each option presents different challenges.

The Benefits Of Mercury In Manufacturing

Mercury has been used in a variety of industrial applications throughout history. For example, it was used to extract gold through amalgamation, create pigments for paints and was even used as a supposed contraceptive in ancient China.

Today, mercury is still used for manufacturing because of its fluidity properties. Various components that rely on mercury use the substance to determine when a component has experienced tilting. The mercury inside such components is much more dense than water and will not evaporate. This makes it ideal for long-term encapsulation, where its fluidity can affect triggers upon movement and shift.

The Downsides Of Mercury In Manufacturing

As mentioned, scientists today understand that mercury exposure can be toxic. However, the harmful effects of mercury exposure weren’t fully understood in the past, and the element was used to manufacture felt hats. Individuals who wore these hats have a propensity for developing dementia; hence the phrase “mad hatter” came into existence.

As a neurotoxin, mercury causes various harmful effects on the brain after prolonged exposure. Memory loss, trembling and numbness can all be signs of mercury poisoning. Additionally, exposure to inorganic mercury may cause gastrointestinal upset, internal bleeding and vomiting. Lastly, elemental mercury exposure may lead to respiratory distress.

Mercury can also be difficult to contain when used in manufacturing. In the manufacturing of thermometers, liquid mercury can be kept in secure containers. In the use of mercury as a gas, the element is odorless and colorless, much like carbon monoxide. Exposure the gaseous mercury can lead to neurological degeneration quickly, and it can be difficult to contain mercury gas once it has escaped.

The Benefits Of Mercury-Free Alternatives In Manufacturing

The obvious benefit of mercury-free alternatives in component manufacturing is eliminating exposure potential. As an added benefit, mercury-free options that use digital technologies may also reduce costs and environmental pollution. Mercury that seeps into the ground can harm the environment and communities, but digital alternatives provide precise measurements without the potential for these threats.

It should also be noted that many industries have regulations that must be followed regarding the use of mercury. In addition, the Environmental Protection Agency (EPA) oversees several laws and regulations pertaining to the use of mercury, including the Mercury Export Ban Act and the Mercury-Containing and Rechargeable Battery Management Act.

The Downsides Of Mercury-Free Alternatives In Manufacturing

While mercury-free alternatives limit mercury exposure and protect communities from mercury poisoning via groundwater, there are some downsides to the switch. First, mercury-free options may be the most costly to implement. The cost of developing digital alternatives to components that use mercury may also take time, and this process may last for years, depending on the complexity of the task.

Additionally, performance may be an issue. For example, batteries that use mercury tend to last longer and provide better overall performance than those that use mercury-free alternatives. This can drive up the costs involved in keeping battery-powered devices running. This can also be a problem where mercury-free alternatives are not readily available. In addition, developing nations can often access mercury more easily than mercury-free alternatives, making the switch difficult for some parts of the world.