In the past, if you wanted to have your design manufactured, you typically had to work with a manufacturing facility to create a physical product. This process involved a number of intricate and time-consuming steps, and for many entrepreneurs who had creative ideas for inventions, the costs involved in contracting with a facility kept manufacturing out of reach. Today, however, 3D printing allows everyday people to create physical items from ideas and designs right in their own homes or workshops. If you’re wondering whether 3D printing is right for you, below are some things to consider:

3D Printing Filaments Are Readily Available

Manufacturing facilities are usually full of large machines, and chemicals are often used in manufacturing as well. This can make it difficult to obtain certain supplies if you plan on contracting with a manufacturing facility since you may need special licenses to purchase certain equipment or chemicals. Even if you aren’t directly handling these items, your name could still be contractually connected to a purchase order since the equipment and chemicals are being applied to your product.

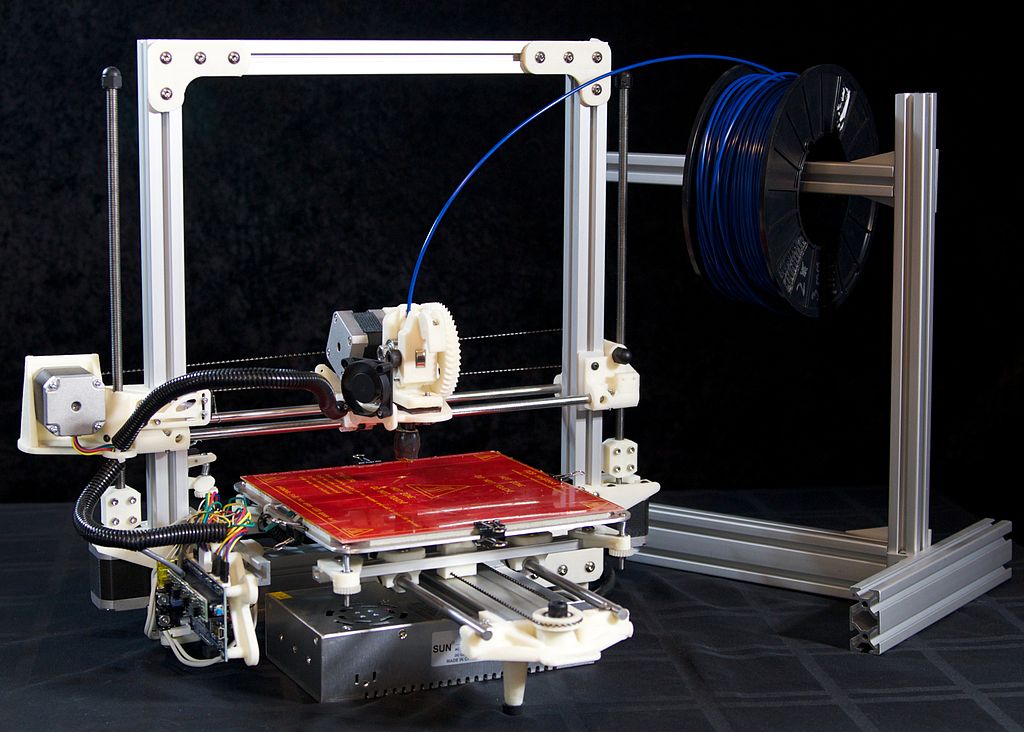

3D printing utilizes filaments made from polymers and alloys. These typically come in spools and are readily available from suppliers across the country. You will still need to exercise caution when using 3D manufacturing filaments since they may give off fumes when heat is applied, but accessing these filaments may be easier than purchasing manufacturing chemicals from a supplier.

3D Printing Can Be Completed In Stages

3D printing also allows for additive processes. Additive manufacturing means building an object up one layer at a time. This process provides greater control over the manufacturing process, and it also offers greater flexibility in scheduling manufacturing. If you need to print a complex item, you can begin the process, stop halfway through and then come back the next day to pick up where you left off. Your 3D printing equipment and software will remember where it was in the process and start back up as if nothing ever happened.

As a bonus, additive manufacturing can offer increased flexibility when it comes to designing objects. Traditional manufacturing usually requires fabricated pieces that are then fit together by machines. Additive manufacturing can build up a design that allows intricate details to be included right from the point of manufacture. There’s often no need to print separate pieces because each piece can be printed as a part of the final design.

3D Printing Is Great For Prototyping

Creating a prototype is a fantastic way to see how the pieces of a complex object will fit together and function before finalizing the design and manufacturing the finished version. Creating a prototype using traditional manufacturing methods can get quite expensive, especially if you need to revise your design and have a new version manufactured. On top of that, you will need to contract out time and space at a manufacturing facility each time you need to create a prototype or revise an existing prototype.

Using 3D printing, you can create multiple prototypes at a much lower cost, and this can help to guarantee a better result in your finished work. Additionally, if you find that you need to make changes to a design after you print a prototype, you can alter your design and print an updated prototype without the hassles of scheduling time and space at a dedicated manufacturing facility. You still need to be smart about your strategy, however, since creating multiple prototypes just because you can might lead to wasted plastic which may become an ecological concern.

3D Printing Is Scalable

When contracting through a traditional manufacturing facility, you usually need to have large orders in order to use the facility’s equipment. If you’re simply wanting to manufacture a small batch or limited run of an item, you may be out of luck.

Purchasing a 3D printer, however, means you can create one item or as many as you need. 3D printers are also available in different sizes and at different price points, so even if you purchase a starter printer today, you can always upgrade to a large printer in the future.